Engineered Experiences

KENNESAW, Ga. | Mar 12, 2019

Students gain hands-on learning through engineering application labs

From delicately machining aluminum automotive parts to 3D printing engine components, Kennesaw State University’s Motorsports Formula SAE Team members are fortifying their studies by manufacturing finely tuned racecars in state-of-the art engineering application labs.

Regular competitors in the national Formula SAE series held by the Society of Automotive Engineers, KSU Motorsports members work year-round to conceptualize, build and race a performance car. The team is composed of about 30 students representing an array of engineering and engineering technology majors, all of whom participate on a voluntary basis.

Over the weekend, KSU Motorsports hosted its seventh annual Formula South Invitational. The on-campus event is held each spring ahead of the larger national competitions in order for the team to gain valuable race day experience and attracts top engineering schools from across the Southeast, including Clemson University, the University of Florida and Mississippi State University. The competition features a series of challenges for each team, including acceleration, skidpad, autocross and a 14-mile endurance race. Proceeds benefited the Robert Glenn Allen Scholarship, which is awarded to a full-time student pursing an undergraduate degree in mechatronics engineering, mechanical engineering or mechanical engineering technology.

For about eight to 10 months a year, the team uses application labs spread throughout the University’s Engineering Technology Center to draft computer-aided designs of the racecar, manufacture parts and measure vehicle performance ahead of regional and national competitions. At the same time, they’re gaining invaluable real-world experience that will guide them as professionals, said Randy Emert, assistant professor of mechanical engineering technology and advisor to KSU Motorsports. The Southern Polytechnic College of Engineering and Engineering Technology has more than 30 application labs covering areas such as electromagnetics, materials strength and robotics.

“Just because something works in a computer simulation doesn't mean it will work in real life,” he said. “As our students work on a project, whether it’s a racecar for the competition team or a capstone project for their major, the labs allow them to test concepts and compare results to computer analysis. Beyond this, the students are gaining a wealth of experience in troubleshooting skills that may be applied to any area of engineering.”

KSU Motorsports president Jordan Ruiz says the team uses as many as five different engineering labs while constructing their racecars, each exposing them to a different skill set they might not have encountered otherwise. Ruiz joined KSU Motorsports shortly after transferring to the University in 2016. Some of his earliest tasks as a team member involved using the machine shop’s various mills and lathes to craft parts that could improve the vehicle’s aerodynamics.

“There are a lot of other schools that might not give you these kinds of opportunities,” Ruiz said. “You might not have the luxury to learn things on the fly once you become a professional, but here we are exposed to all kinds of equipment that we may encounter in industry. As a student, I feel like that gives me a huge advantage.”

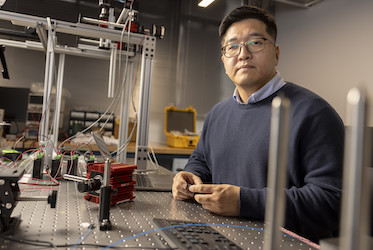

Joshua Bray, a mechatronics engineering student, said the labs are also a great way for students to receive exposure to concepts prior to upper-level courses. Before taking a circuits course, he was taught about basic level electrical circuits by other team members in the automotive lab. Due to his involvement with KSU Motorsports and his extensive lab experience, Bray was later invited to work on an industry project with Ying Wang, an associate professor of mechatronics engineering.

Systems and industrial engineering student Austin Deaver, who uses the University’s 3D Center to craft vehicle components, said the knowledge he has gained in each of the labs could be what sets him apart in future job interviews.

“For me, having labs like the machine shop and the 3D Center are allowing me to gain the knowledge that I hope to one day use in my career,” he said. “Without them, competition teams like Formula SAE wouldn’t be possible.”

– Travis Highfield

Photos by Rob Witzel; Video by David Johnson

###

The Southern Polytechnic College of Engineering and Engineering Technology at Kennesaw State University offers students hands-on learning experiences and produces Georgia’s next generation of work-ready engineers. It is the second largest engineering college in Georgia, serving more than 4,000 students and offering 20 undergraduate and graduate degrees in engineering and engineering technology led by industry-expert faculty in the University’s state-of-the-art facilities.

Related Stories

A leader in innovative teaching and learning, Kennesaw State University offers undergraduate, graduate and doctoral degrees to its more than 45,000 students. Kennesaw State is a member of the University System of Georgia with 11 academic colleges. The university’s vibrant campus culture, diverse population, strong global ties and entrepreneurial spirit draw students from throughout the country and the world. Kennesaw State is a Carnegie-designated doctoral research institution (R2), placing it among an elite group of only 7 percent of U.S. colleges and universities with an R1 or R2 status. For more information, visit kennesaw.edu.